Systems

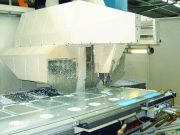

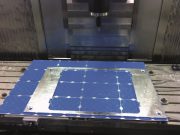

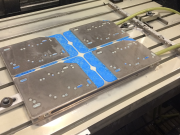

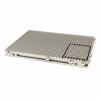

With VAC-MAT polymer mats from Witte, workpieces can be machined completely in one vacuum clamping process. VAC-MAT allows milling of cutouts, slots etc. Even machining contours and chamfers – normally only possible with special chucks – can be successfully carried out. During the machining process, up to 70 percent of the surface material can be removed without losing vacuum or any milled parts being unintentionally released. At the same time costly reworking, such as breaking off the workpieces, deburring or clamping using clamps or double-sided tape is no longer required.

Applications

- grinding

- milling

- drilling

- 5-side machining, including all cutouts

Special advantages

- high holding force

- clamping surface has high friction coefficient

- through milling of outer and inner contours possible

- accurate and clean workpiece cutting edges without burrs

Handling

- significantly shorter preparation times because workpieces are clamped within seconds

- no seals required

- gentle contact to workpieces and clamping surfaces

- no scratching of surfaces

- no special fixturing necessary

- modular versions for large clamping surfaces