Developed for special tasks

QuadroVac is the innovative vacuum clamping system especially for strongly contoured workpieces which have to be machined in many axes.

"QuadroVac" is primarily used for milling, drilling and thread cutting on small to medium-sized parts made of wood, plastic, glass or metal, for example on cast parts. Also on those with steps, pockets or cutouts.

With its freedom of configuration, the QuadroVac vacuum clamping system is suitable both for series manufacturing and for holding frequently changing part shapes.

Modular and individually combinable configuration

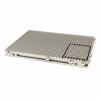

The QuadroVac system consists of modularly combinable vacuum base chucks in various formats, for example 300 x 450 millimeters. These in turn accommodate clamping elements of the same size in a grid of 150 x 150 millimeters - individually distributed as required and according to the shape of the workpiece to be clamped.

Various elements are available with either a flat clamping surface, or for covering areas of the base plate that are not required, or which can be milled flat by the user at the desired height - as well as with variable molded sealing elements. The latter ensure an unprecedented level of flexibility in five-side machining of clamped small and medium-sized workpieces.

Advantages, capabilities, areas of application

- 5-side machining possible including cutouts.

- Exact mapping of the workpiece contour is possible thanks to the fine grid using suction cups.

- Material-friendly contact surface (PVC).

- Can also be used on rough-cut surfaces and raw, unmachined clamping surfaces.

- Machining of chamfers, radii and undercuts on the outer workpiece contour above and below is possible.Modularly extendable.

- Can be used vertically and horizontally.